| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

Basic installation of roller bearings

1) Wash the bearing with kerosene, press it into the bearing seat, fill the rollers of the outer ring of the bearing with Shell No. 3 lithium base grease to two-thirds full, apply it evenly with a clean hand, install the ntn bearing gland, and use The tightening bolt of the bolt anti-loosening glue presses the bearing gland;

2) The bearing is a cylindrical roller bearing with a separable inner and outer sleeve, and the inner sleeve of the bearing should be sleeved on the shaft and in place;

3) Install the bearing seat on the housing, if there is a grease injection hole, align the position. Tighten the bearing seat with fastening bolts coated with bolt anti-loosening glue;

4) Install the inner and outer eccentric block on the shaft and place it in place. If there is a shaft key, install the shaft key in the keyway and then install the outer eccentric block, and install the shaft retaining ring on the shaft;

5) Tighten the fastening bolts of the eccentric block, turn the adjustable eccentric block to the angular position before removal and tighten the fastening bolts. After the above assembly is completed, the shaft should have a certain axial series movement;

6) The protective covers at both ends of the upper vibration motor are fastened with screws.

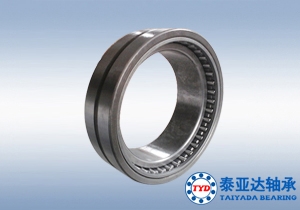

Roller bearing manufacturers can guess what it looks like from its name. The outer ring of the roller bearing adopts a full-complement cylindrical roller bearing with a thicker outer ring wall. The outer diameter of the roller has a cylindrical shape and an arc shape. It can be designed to match the raceway surface according to the application. With this outer ring, the roller can roll directly on the raceway and can withstand heavier loads and impact loads. Its advantage is that the internal friction coefficient is small, so it has less friction to overcome, and the thin oil has good fluidity, and it is easy to enter the friction surface of each lubrication point. It has a good effect and can remove impurities adhered to the friction surface and due to grinding. The produced metal particles are taken away.

1) Wash the bearing with kerosene, press it into the bearing seat, fill the rollers of the outer ring of the bearing with Shell No. 3 lithium base grease to two-thirds full, apply it evenly with a clean hand, install the ntn bearing gland, and use The tightening bolt of the bolt anti-loosening glue presses the bearing gland;

2) The bearing is a cylindrical roller bearing with a separable inner and outer sleeve, and the inner sleeve of the bearing should be sleeved on the shaft and in place;

3) Install the bearing seat on the housing, if there is a grease injection hole, align the position. Tighten the bearing seat with fastening bolts coated with bolt anti-loosening glue;

4) Install the inner and outer eccentric block on the shaft and place it in place. If there is a shaft key, install the shaft key in the keyway and then install the outer eccentric block, and install the shaft retaining ring on the shaft;

5) Tighten the fastening bolts of the eccentric block, turn the adjustable eccentric block to the angular position before removal and tighten the fastening bolts. After the above assembly is completed, the shaft should have a certain axial series movement;

6) The protective covers at both ends of the upper vibration motor are fastened with screws.

According to the shape of the rolling elements, it can be divided into ball bearings and roller bearings. Roller bearings are classified into cylindrical roller bearings, needle roller bearings, tapered roller bearings and spherical roller bearings according to the types of rollers.

According to whether it can be adjusted during work, it can be divided into self-aligning bearings-the raceway is spherical, which can adapt to the angular deviation between the axis of the two raceways and angular motion bearings and non-aligning bearings (rigid bearings) ---- Bearings that can resist the angular deviation of the axis between the raceways.

is divided into single row bearings, double row bearings and multi-row bearings according to the number of rows of rolling elements.

is divided into separable bearings and non-separable bearings according to whether its parts (rings) can be separated.

according to its structure shape (such as with or without filling groove, with or without the shape of the inner, outer ring and ferrule, the structure of the rib, and even with or without the cage, etc.) can also be divided into a variety of structural types.

According to its outer diameter size, it is divided into miniature bearings (<26mm), small bearings (28-55mm), small and medium bearings (60-115), medium and large bearings (120-190mm), large bearings (200-430mm) and special bearings. Large bearings (>440mm).

is divided into motor bearings, rolling mill bearings, main bearings, etc. according to application areas.

is divided into ceramic bearings, plastic bearings, etc. according to the material.