| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

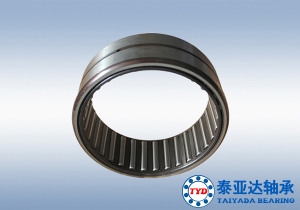

Large-capacity cylindrical roller bearing manufacturers have the high load-carrying capacity of full complement bearings and the high-speed capability of cage bearings. They are designed for applications such as industrial gearboxes, wind turbine gearboxes and mining equipment. Single row cylindrical roller bearings are available in various designs, series and sizes. The main design differences between the bearings described in this section are:

Cage design and material

Configuration of inner ring and outer ring edge

Features and advantages

The open rib design combined with the roller end and surface finish promotes the formation of a lubricating film, thereby reducing friction and increasing axial load capacity.

long lasting

Due to the roller's logarithmic profile, the circumferential stress in the roller/track contact area is reduced, and it is also sensitive to misalignment and shaft deflection.

Improve operational reliability

The smoothness of the contact surface between the roller and the raceway is conducive to the formation of a hydrodynamic lubricating film.

Removable and interchangeable

The separable parts of SKF cylindrical roller bearings are interchangeable. This function simplifies assembly and disassembly, inspection and maintenance procedures.

Suitable for high speed

The cage design can achieve high speed, rapid acceleration and peak load. Crossed roller bearings are characterized by high rotation accuracy, and because of the orthogonal arrangement of cylindrical rollers, they can bear loads in all directions.

These bearings are particularly suitable for installations with high dynamic loads or limited radial directions. They have undergone strict adjustments on the housing. The positioning thrust bearing does not require a shoulder pad or a retaining ring, and it can realize a simple and economical bearing housing hole design. Suitable for various applications, such as automobile and truck transmissions, agricultural and construction equipment, pumps and compressors, and two-stroke engines. Note: Use printer installation. Or place a special tool on the hammer, because the blow may cause local deformation or brittle fracture.