| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

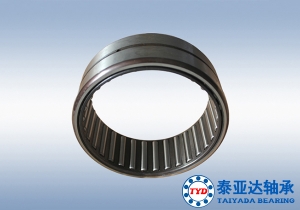

Roller bearing manufacturers have a steel cage and an oil hole in the outer ring, which are suitable for applications with high dynamic and static loads. It has a reduced cross-section (no inner ring) and can be used in restricted installation space, while the thick one-piece outer ring has an integral end flange to provide axial guidance for the cage and rollers. The cage can provide uniform guidance of the guide wheels to reduce friction, vibration and noise during high-speed operation, and the cage is made of hardened steel, which has higher strength, rigidity and heat resistance than the nylon cage. There is a lubrication groove and an oil hole in the outer ring for lubrication at a proper position. The needle rollers are made of high-hardness chrome alloy steel to improve durability and heat resistance, and have contoured ends to optimize the distribution of contact stress. Such radial needle roller bearings can be used in a variety of applications, such as automobile and truck transmissions, agricultural and construction equipment, pumps and compressors, and two-stroke engines.

Heavy-duty single row radial needle roller bearings, suitable for applications with high dynamic and static loads

High load-bearing capacity and reduced cross-section for use in limited spaces

Steel cage guide rails and evenly distributed rollers to reduce friction, vibration and noise

One-piece thick outer ring with flange provides axial guidance for cage and rollers

Lubrication grooves and oil holes can be lubricated in appropriate positions

Roller bearings use rolling elements to maintain the spacing between moving parts to reduce rotational friction and support radial and axial loads. These elements can be one of the following types: spherical, cylindrical, spherical, cylindrical, needle-shaped, spindle-shaped, or tapered. The two ends of the roller bearing can be opened (the shaft can pass through), or one end can be opened and the other end can be closed. The open end can be sealed or shielded to protect the bearing from solid contaminants and moisture, which will shorten its service life. If one end is sealed, the sealing member is an elastic lip in contact with the shaft. If it is shielded, the shield is a non-contact lip, usually made of metal. Rolling bearings have a wide range of applications, from agricultural machinery to conveying equipment, robots, dental equipment, elevators, rolling mills, and ship rudder shafts.