| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

The shells of composite roller bearing manufacturers are divided into adjustable and non-adjustable according to the different structural design.

Adjustable can be divided into gear adjustment, hex adjustment, nut adjustment

The gear adjustment is that both ends of the inner ring of the side roller (that is, the mandrel) are processed into an eccentric gear shape, and the connecting part of the mandrel and the shaft head is also designed as a gear shape. The whole is adjusted by adjusting the eccentricity of the gear to adjust the protrusion of the side roller The height of the composite roller.

Hexagonal eccentric adjustment is based on the same principle as gear adjustment. The tail gear is hexagonal eccentric. The overall height of the composite roller can be adjusted by adjusting the hexagon. Compared with gear adjustment, the hexagonal adjustable composite roller has higher stability and load strength.

The nut adjustment means that the side rollers are installed on the shaft frame and installed inside the shaft head. The protrusion of the shaft frame (side roller) is adjusted by the two set screws on the head of the shaft head to adjust the overall height of the bearing. Compared with the above two In this way, the nut adjustment is the latest design, no need to disassemble the bearing, and the adjustment is simple, convenient and quick.

The inner ring (core shaft) of the non-adjustable side roller is cylindrical and connected to the shaft head, which is rotatable. Compared with the adjustable type, this structure is suitable for precise and functionally stable equipment that does not need adjustment, and the cost is relatively low. 1) Main roller

The main roller is the main bearing body in a set of composite rollers. It mainly bears vertical load and impact load, and has strong impact resistance, wear resistance and corrosion resistance. Since the main roller is a full complement roller bearing, it can also be used alone as a one-way bearing.

2) Side roller

The side roller is the second carrier of a set of composite rollers, which mainly bears horizontal load, and also has strong impact resistance, wear resistance and corrosion resistance. The side rollers are designed with no inner ring and full needles, and a mandrel replaces the inner ring and the shaft head to carry the load.

3) Shaft head

The shaft head is used as the connection part of the composite roller and the machine equipment. Usually the shaft head head is designed to be chamfered for easy installation. The shaft head can be directly welded-connected to the equipment, or the shaft head can be welded-connected to the Assemble the connecting plate and the equipment on the connecting plate of the round hole.

4) Cover plate

The function of the cover plate is to fix the side rollers installed inside the shaft head and the main rollers outside the shaft head with nuts and thread glue on the shaft head and tail.

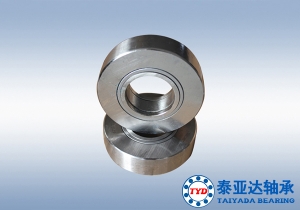

The outer ring adopts a full complement cylindrical roller bearing with a thicker outer ring wall. The outer diameter of the roller has cylindrical and arc shapes, which can be designed to match the raceway surface according to the application. Using this outer ring, the roller can roll directly on the raceway and can withstand heavier loads and shock loads. The bearing has a sealed structure and is filled with grease to provide long-term effective lubrication. Users can avoid lubrication. For harsh operating conditions, a channel for replenishing grease can be designed to increase the service life of the bearing.

Composite roller bearings are used in forklift masts, mobile handling systems, lifting systems and other equipment

Composite roller bearing, also known as combined roller bearing, is assembled by the combination of radial and axial bearings, which simplifies the structure, effectively saves installation space, and is convenient to use. It only needs to weld the shaft head in the mounting plate hole without disassembly. The entire bearing and accessories are highly replaceable.