| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

The temperature detection of the outer cylindrical roller bearing requires a certain time after the bearing is operated. This is a standard principle problem for our detection. Bearings require long-term operation. If the temperature is too high, certain unsafe elements will occur. As a professional roller bearing manufacturer, we need to ensure the safety of our customers. Therefore, we need to conduct sampling tests before leaving the factory. Factory sold.

The temperature of the bearing gradually rises with the beginning of the bearing operation, and reaches a stable condition after 1-2 hours. The normal temperature of the bearing varies with the heat capacity, heat dissipation, speed and load of the machine. If it is smooth and the equipment part is suitable, the bearing temperature will rise sharply and abnormally high temperature will occur. At this time, it is necessary to interrupt the operation and take necessary precautions.

The use of thermal sensors can monitor the operating temperature of the outer spherical bearing at any time, and automatically alarm when the temperature exceeds the specified value or intermittently avoid combustion shaft incidents.

There are many classifications of bearings. Spherical bearings are one of them. Have we understood the applications of Spherical Bearings? What are the general applications of Spherical Bearings? Let's take a look together.

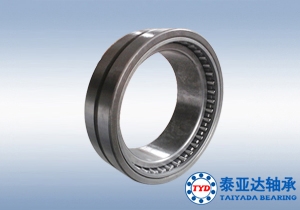

Outer spherical cylindrical roller bearing

Outer spherical bearings are widely used in rotating motor parts. As well as completing a smooth and quiet rotation, they also perform an important function, passing the load on the motor.

The global agenda of protecting the environment is rising, electricity is becoming more and more popular as a power source, and customers increasingly need motors with low energy consumption. There are also requirements for longer operating life, as a technique, and even high reliability.

1) Wash the bearing with kerosene, press it into the bearing seat, fill the rollers of the outer ring of the bearing with Shell No. 3 lithium base grease to two-thirds full, use clean hands to modify it evenly, install the ntn bearing gland, and use to paint The tightening bolt of the bolt anti-loosening glue presses the bearing gland;

2) The roller bearing is a cylindrical roller bearing with separable outer and inner sleeves. The inner bearing should be sleeved on the rotating shaft and in place;

3) Install the roller bearing seat on the casing, and if there is a lubricating grease hole, align the position. Tighten the bearing seat with fastening bolts coated with bolt anti-loosening glue;

4) Install the front and back side pain block on the shaft and place it in place. If there is a shaft key, install the shaft key in the keyway and then install the outer side pain block, and install the shaft retaining ring on the shaft;

5) Tighten the fastening bolts of the migraine block, turn the adjustable migraine block until it reaches the position of the viewpoint before removal, and tighten the fastening bolts. After the above assembly is completed, the shaft should have a certain axial series movement;

6) Use screws to fasten the protective covers on both ends of the oscillating motor.

The damage of the roller bearing can be said to be equal to peeling, indentation, rust, crack, abrasion, etc., which will be reflected in the vibration measurement of the roller bearing. Therefore, the roller bearing manufacturer can measure the size of the oscillation through the use of a special bearing oscillation measuring device, and the specific abnormal situation can be inferred through the frequency dispersion. The measured value is different due to the operating conditions of the roller bearing or the position of the sensor device, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Maintenance of roller bearings: thin oil and smooth. The advantage is that the coefficient of internal conflict is small, so it takes less time to overcome conflicts. The thin oil has good fluidity and is easy to enter the conflict surface of each smooth point. It has an outstanding cooling effect and can remove impurities adhering to the conflict surface and because of grinding. The produced metal particles are taken away. The defect is that the oil film cannot withstand a large unit pressure and has high requirements for sealing. High-speed presses generally use large-flow thin oil for smoothness, which can take away the heat generated by the conflicting pairs.

The correct use of roller bearings can achieve fatigue life. But if accidental early damage occurs, it can no longer be used. Different from exhausted lifespan, this early damage is called a fault or accident. It is mostly caused by inadequate consideration of equipment, operation, and smoothness, foreign matter intruding from the outside, or lack of research on shafts and bearing seats.

The damage state of the bearing, such as the abrasion of the ring rib of a roller bearing, may be caused by lack of smoothing agent, improper grade, defective oil supply and discharge structure, foreign matter intrusion, bearing device error or excessive shaft deflection. It may also be caused by a combination of the above-mentioned reasons.

Therefore, it is difficult to know the cause of the damage only by querying the bearing damage. However, if we clarify the situation before and after the fault occurs on the basis of a full understanding of the machinery, working conditions and external structure of the bearing, and then analyze the damage of the bearing and a variety of related reasons, we can prevent the same fault from happening again.

From the name of the roller bearing, you can guess what it looks like. The outer ring of the roller bearing adopts a full-complement cylindrical roller bearing with a thicker outer ring wall. The outer diameter of the roller has a cylindrical shape and an arc shape. According to the application, it is designed to cooperate with the raceway surface. With this outer ring, the roller can roll directly on the raceway and can withstand heavier loads and impact loads. Its advantage is that the internal conflict coefficient is small, so it costs less to overcome conflicts, the thin oil has good fluidity, and it is easy to enter the conflict surface of each smooth point. It has an outstanding effect and can remove the impurities adhering to the conflict surface and because of grinding. The produced metal particles are taken away.