| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

The application of automobile water pump shaft bearing mainly accepts radial and axial combined load, which is mainly radial load. It is widely used in transmission parts such as active bevel gears, front and rear hubs, reducers, and differentials of automobiles. The permissible inclination angle of the water pump shaft bearing does not exceed 2'(with an inclination condition). The tapered roller bearing generally does not allow the shaft to be inclined relative to the housing hole.

The automobile water pump shaft bearing is a type of bearing. The cage material is usually reinforced nylon 66, and the seal ring material is generally nitrile rubber. When the requirements are higher, a fluorine rubber seal ring can also be used.

The cooling system of the car engine is an important part of the car. The stability and reliability of the system and the compactness of its structure. Not only directly affects the mechanical properties of the car, but also affects the overall appearance of the car. For this reason, automobile engine cooling systems produced by industrially developed countries generally use cooling water pump shaft bearings.

The function of the automobile water pump is to circulate the cooling water between the engine water jacket and the radiator to ensure the normal operation of the engine within a certain temperature range; the water pump is mainly composed of the shell, pulley, shaft and bearing, slip ring seal and impeller The bearing has a decisive effect on the service life of the entire pump, and also determines the main performance of the pump such as noise.

Based on the structural characteristics of the shaft-connected bearing, the inner ring of the shaft as the bearing should have a contact fatigue life corresponding to the bearing. When the bearing is running, the surface of the raceway and the rolling element will form cracks and expand under the long-term action of the cyclic load, until the surface of the raceway or the rolling element is fatigued and peeled. Once such a situation occurs during the operation of the shaft-connected bearing, its vibration and noise will increase sharply, thereby making the whole machine unable to work. It can be seen that in order to improve the service life of shaft bearings, in addition to considering the wear resistance and fatigue strength required as a shaft, it must have a higher contact fatigue life.

The steel selected for conventional shaft bearings (including shafts, outer rings, steel ball rollers) is high carbon chromium bearing steel (GCr15). Because high-quality bearing steel is smelted through vacuum deoxidation, electromagnetic stirring, and has less oxide content, it can withstand greater contact pressure stress while also withstanding greater high variable tensile stress. After heat treatment, the hardness of the shaft raceway It is 58-62HRC. The hardness of the ring raceway is 60-64HRC, and the hardness of steel balls and rollers is 61-65HRC. When the shaft and outer ring are made of carburized bearing steel, the raceway hardness is 60-64HRC. The material of the cage is usually reinforced nylon 66, and the material of the sealing ring is generally nitrile rubber. When the requirement is higher, the fluorine rubber sealing ring can also be selected.

Because the water pump shaft bearing works at high speed and high temperature, the lubrication conditions directly affect the operating life of the shaft and shaft. Usually, imported high-grade grease with higher dropping point and better consistency is used, and the sealing ring is usually used. The large surplus radial contact seal ensures that the bearing does not lose oil for many years.

What are the important components of the automobile water pump shaft bearing?

The practical internal clearance of automobile water pump shaft bearing greatly affects the service life and performance of the bearing. When selecting the original radial clearance, it is necessary to consider the reduction in clearance caused by the interference fit between the outer ring of the bearing and the housing hole. , But also consider the reduction in clearance caused by the thermal expansion of the relevant components caused by the temperature rise, and the recommended amount of interference.

Water pump bearings are delicate mechanical parts, so please pay special attention when installing them. When installing, use auxiliary tools to stop mechanical press-in. It is strictly forbidden to transmit pressure through rolling elements. At the same time, the bearing should be prevented from being damaged by external impact. The roundness of the water pump housing hole should be controlled within 10μm and the cylindrical degree within 20μm.

water pump is composed of water pump housing, shaft bearing, water seal, impeller, fan and transmission parts. Shaft bearing is an important part of water pump. Due to the high speed of the water pump, the speed of the ordinary water pump is up to 6000r/min, and the speed of the high-speed water pump is as high as 9000r/min. Therefore, the shaft bearing is required to have a higher load-bearing capacity, so as to meet the pump's life expectancy at a certain speed. . The space position of the water pump is limited, the heat dissipation area is small, and the working conditions are bad. Therefore, the shaft bearing should be able to meet the requirements of maintaining normal operation under high temperature without reducing the bearing capacity of the bearing. The sealing of the bearing has certain difficulties, and its sealing reliability and durability will directly affect the operability of the water pump.

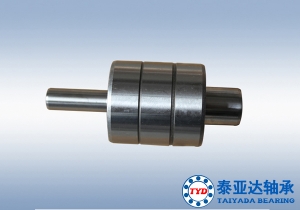

A double-supported shaft system with a simplified structure. The two supported bearings have no inner rings. The raceways of the rolling elements are directly made on the shaft. The outer rings of the two supported bearings are made into a whole. Both sides of the ring are sealed. The parts are sealed to form the assembly of the shaft sleeve. Under the same load capacity, its radial dimension is smaller than that of ordinary type bearings; under the same radial dimension condition, its load capacity is greater than that of ordinary type bearings. Because of its good rigidity, rotation, simple structure, and easy assembly and disassembly, many prosperous western countries such as the United States, Japan, Germany, etc. have adopted shaft bearings with this structure. At present, some automotive cooling water pump bearings in China have not adopted this advanced structure, but still use two deep groove ball bearings and shafts to form a shaft system. This type of structure has many links, complex assembly procedures, low efficiency, and poor rigidity. It is being replaced by advanced automotive water pump shaft bearings. Various types of automobile water pump shaft bearings have been widely used in domestic automobiles and imported models.