| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

Do you know how to solve the heating phenomenon in the operation of the roller bearing? Let's take a look.

Matters needing attention in the application of rolling bearings: INA bearings are delicate components, and their applications must be terminated relatively carefully. No matter how excellent the performance of rolling bearings is, if the application is not good, it is not easy to get the predicted performance. The matters needing attention in the application of rolling bearings are as follows:

⑴. Persistent rolling bearing and cleaning around. Even the small floating dust invisible to the eyes can cause harm to the roller bearing. Therefore, it is necessary to persevere in cleaning around, so that the floating dust will not invade the rolling bearing.

⑵.Apply carefully. In the application, the rolling bearing is given a strong impact, which will cause scars and imprints, which will become the cause of safety accidents. In more serious cases, cracks and ruptures may occur, so care must be taken.

⑶. Appropriate practical tools should be used. To avoid replacing it with the current special tools, it is essential to use the appropriate special tools. Such as special-purpose sleeve specifications, punching machines, etc.

⑷. Pay attention to the rust of the rolling bearing. When actually operating INA bearings, sweat in your hands can become the cause of rust. Pay attention to the actual operation with clean hands, it is best to carry rubber gloves as much as possible.

⑸. It is not necessary to disassemble the packaging of the rolling bearing before the equipment preparation work is carried out to prevent environmental pollution.

The service life of the roller bearing is more sensitive to the load-to-speed ratio. Therefore, if it is possible for a multi-level rotating shaft, it is advisable to reduce the speed greatly to a later proportional series; for the machine tool spindle bearing, if it is very It is possible to appropriately allocate the distance between the external load support force and the supporting point of the rolling bearing to try to reduce the load on the spindle bearing of the machine tool, and try to stabilize the load on the spindle bearing of the machine tool to avoid impact and vibration, which requires the location of the rolling bearing equipment The appearance design and precision of the parts are sufficient and high, the backlash and mutual cooperation of the rolling bearing are selected appropriately, and the precision of the rolling bearing equipment is excellent.

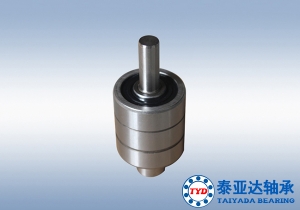

The shaft parts of CNC lathes are very spindle bearings, which are generally assembled with rolling bearings or rolling bearings and rotate at a high speed ratio, which sometimes causes high heat generation. If this kind of situation is not cleaned immediately, it will cause the rolling bearing to over-temperature, and the relative position temperature of the CNC lathe will rise, causing thermal deformation. When it is more serious, the spindle bearing and the tailstock will not be high. I think it only harms the precision and precision of the CNC lathe itself. Machining accuracy, and will burn the rolling bearing. The reason for the hot roller bearing and the cleaning method are shown in Table 1.

Causes of hot rolling bearings and cleaning methods

1. Reason: low precision of rolling bearings. Method: use rolling bearings with standard accuracy levels

2. Reason: the spindle bearing is bent or the housing hole is not centered. Method: repair the spindle bearing or housing

3. Reason: the transmission belt is too tight. Method: adjust the transmission belt to make it tight and loose properly

4. Reason: poor finish. Method: use standard models of finish materials and clean them appropriately

5. Reason: Low installation quality Method: Develop installation quality

6. Reason: the method of running circle in the inner casing of the rolling bearing: replace the rolling bearing and related damaged components

7. The method of large axial force: clean and adjust the sealing gap between 0.2~0.3mm, change the diameter of the centrifugal impeller balance hole and check the static balance value

8. Destruction method of rolling bearing: replace the roller bearing.