| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

Expand all polyurethane and metal bonding, bonding with iron is better than bonding with other metals. Degreasing and rust removal should be done before encapsulation, and then Moroccan glue should be applied. After drying, the metal core should be kept at 120°C for 1 hour.

Apply some Chemlock glue to the covered area

It is necessary to spread out all sandblasting. The roller bearings are then degreasing. The roller bearings are then pre-cured with the adhesive! Roller bearings!

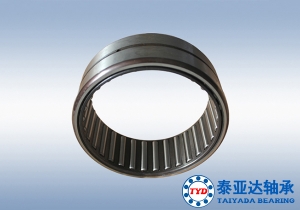

The application frequency of needle roller bearings in the industrial field has risen linearly, and their own sizes and specifications of different sizes can be docked with installation occasions of different nature. The high quality of needle roller bearings is a key measurement index, which is proportional to the length of the service life. As for which brand of needle roller bearing is better, you must focus on the horizontal comparison of manufacturers, and the conclusions drawn are more accurate. After careful observation, it is found that the advantages of needle roller bearings can be summarized in three aspects.

1. The compact structure can withstand greater gravity and pressure

The advantages of needle roller bearings are shown in their good load-bearing performance, their own structure comes with compact properties, and all the components used are tightly connected together. In this case, regardless of the size and volume of the bearing, the compact structure will give the bearing a corresponding load-bearing capacity, which of course also includes the load-bearing capacity for pressure.

2. The three-dimensional circular appearance is more solid and durable

The advantages of needle roller bearings are also reflected in their appearance, which is a three-dimensional circular appearance, so that the bearing will not be easily damaged, and it will become more solid and durable. Imagine that in a busy industrial field every day, equipment will enter high-intensity operation. If the bearing itself is not solid enough, it is difficult to maintain stability in this state.

3. The integrated structure reduces the frequency of failures

The advantage of needle roller bearings also lies in the suppression of failures. They use a seamless structure, and the position of each component will not be easily moved, which eliminates the existence of deviation from the root cause. As long as the correct use method is followed, the potential failures and problems of the bearing will be controlled, and the frequency of problems will naturally be reduced.

The application frequency of needle roller bearings in the industrial field has risen linearly, and their own sizes and specifications of different sizes can be docked with installation occasions of different nature. The high quality of needle roller bearings is a key measurement index, which is proportional to the length of the service life. As for which brand of needle roller bearing is better, you must focus on the horizontal comparison of manufacturers, and the conclusions drawn are more accurate. After careful observation, it is found that the advantages of needle roller bearings can be summarized in three aspects.

1. The compact structure can withstand greater gravity and pressure

The advantages of needle roller bearings are shown in their good load-bearing performance, their own structure comes with compact properties, and all the components used are tightly connected together. In this case, regardless of the size and volume of the bearing, the compact structure will give the bearing a corresponding load-bearing capacity, which of course also includes the load-bearing capacity.

2. The three-dimensional circular appearance is more solid and durable

The advantages of needle roller bearings are also reflected in their appearance, which is a three-dimensional circular appearance, so that the bearing will not be easily damaged, and it will become more solid and durable. Imagine that in a busy industrial field every day, equipment will enter high-intensity operation. If the bearing itself is not solid enough, it is difficult to maintain stability in this state.

3. The integrated structure reduces the frequency of failures

The advantage of needle roller bearings also lies in the suppression of failures. They use a seamless structure, and the position of each component will not be easily moved, which eliminates the existence of deviation from the root cause. As long as the correct use method is followed, the potential failures and problems of the bearing will be controlled, and the frequency of problems will naturally be reduced.