| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

1. From the application point of view, needle rollers are mainly used in occasions where space is limited, so they are widely used in automobiles, motorcycles, and textile machinery. And the inner ring of the needle roller is optional. To put it bluntly, if the hardness and roughness of the shaft meet the requirements, the inner ring can be omitted (the space is inherently limited), but if the shaft is relatively low or soft, It needs to be equipped with an inner ring as a raceway. The roller is often used to support the floating end of the shaft to absorb the expansion of the shaft. The four rows of rollers on the binding machine are mostly used, mainly because the rollers have a very large bearing capacity.

2. From the shape point of view, there are two standards for distinguishing between needle rollers and rollers: The first is the ratio of 2.5 as the demarcation point. The second standard is based on a ratio of 4.

3. From the perspective of force, the needle roller does not bear axial force at all (the end surface of the needle is not worn, if it contacts the shoulder, the friction is very large), and the roller, if the raceway has a shoulder If it can withstand a certain axial force, of course it should not be too large, and the principle is not to exceed 1/10 of the radial force.

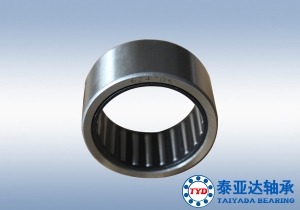

Features of Needle Roller Bearing Inserts

These types of inserts are also called adaptive radial needle roller bearings. They are commonly used in installations and installations in industries such as agriculture, food processing, and printing.

Even though needle bearing inserts are usually sold together with housing units, they can be sold separately as products.

These inserts provide users with several different functions, such as:

Shell Shell can be made of different materials such as stainless steel, cast iron or pressed steel. They can also be made of zinc or nickel.

Compared with double row or single row ball needle roller bearings, they can withstand larger loads.

The relubrication process is easier.

There is an anti-rollover option available.

How do they work?

There is a looser needle roller bearing insertion style to choose from. This type of insert has a wider inner ring in the needle bearing. The inner ring extends far beyond both sides of the outer ring.

One side of the extension allows the use of heavy-duty seals on the needle bearing, and the other side of the extension simultaneously accommodates the heavy-duty seal and the locking device.

These types of needle bearing inserts are usually used for heavier applications.

The requirements for these inserts are getting higher and higher, so that some manufacturers have begun to manufacture inserts with both narrow ring and wide ring inserts in needle bearings. The combination of these two features makes an affordable way to have a needle roller bearing that can be adapted to any application.

1 Needle roller bearings include many types, such as one-way needle roller bearings, automotive needle roller bearings, drawn cup needle roller bearings, etc.

2 During the needle roller bearing process, there is a blank forming process. Of course, don’t neglect the need for a good design of the bearing before this; then the blank is deburred.

3 Afterwards, the roughness of the needle roller bearing will be processed, which is a very important step in the production process; then the rough, fine, and final grinding rolling surfaces are carried out, which is to meet the production of some special requirements of the bearing; super finishing rolling Polished surface or sawdust.