| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

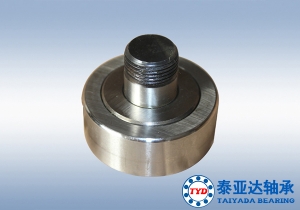

Because of the wide range of uses and the good quality, roller bearings can be more popular in this market, and the benefits and advantages of bearings can become more obvious this week.

Using this kind of outer ring, the roller can directly migrate and transform on the raceway, and can withstand heavier load and impact load. Despite having a small cross-section, the bearing still has a higher load capacity. Therefore, it is especially suitable for places with restricted radial space.

When the workpiece of Changzhou roller bearing manufacturer is severely overheated, coarse grains will occur, and at the same time, the amount of 8 ferrite in the steel will increase, which is easy to cause deterioration of the hot working performance of the workpiece. Then, how should we prevent the bearing workpiece from overheating?

(1) Strictly control the casting heating temperature and heating and heat preservation of stainless steel box and flange parts to prevent the workpiece from overheating and causing the workpiece to have the defect of coarse grains.

(2) In the forging production of workpieces, if the casting ratio is too small, the final forging temperature is too high, and the defects of coarse-grain structure are easy to appear. The casting ratio of Changzhou Fangyi bearing workpiece should be suitable and sufficient, and the final forging temperature should be moderate.

Generally speaking, bearing is a very critical spare part commodity that is frequently used in contemporary industrial production processes. Because of the hierarchical use of the bearing, the bearing has been divided into many different types such as rolling bearings and roller bearings in detail. So what are the key issues that these demanding customers must pay attention to in the process of buying roller bearings?

What are the common problems when choosing roller bearings

1. Pay attention to whether the raw materials are qualified

Most of the roller bearings on the market are all shaped out of some unique stainless steel plates through a detailed extrusion process. The type and quality of the stainless steel plates that manufacturers often use in the processing process are immediately related to the quality level of the bearing products, so pay attention to knowing whether the clearly produced raw materials are qualified or not is the first common problem for customers when choosing roller bearings.

2. Pay attention to whether the technical parameters are qualified

In terms of the index parameters of bearing products, it mainly includes the strength, fatigue relief characteristics and corrosion resistance of the products. Therefore, when selecting roller bearings, you must know the news of this industry in detail with the manufacturer or the agent. After all, all the index parameters can be qualified or even exceed the specifications. The bearing shaft is regarded as a real high-quality product. .

Three, pay attention to whether the specifications are suitable

After clarifying that the performance in all areas of the bearing is very good, customers have an area that must be paid attention to. This is to clearly understand their requirements, that is, which specifications and sizes of roller bearings can be suitable for their products. Therefore, after comparing which roller bearing has the same price, the customer must have a detailed understanding of the product model and specification problems.

In summary, if customers want to buy better quality roller bearings, they must pay attention to these three aspects. Generally, in the selection process, it is necessary to inquire about the quality of the raw materials used to make the bearing shaft for a while, and also to make a sound investigation on whether the various technical parameters of the roller bearing can be completely qualified, in addition to this In addition, you must pay attention to choosing products of suitable size specifications.