| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

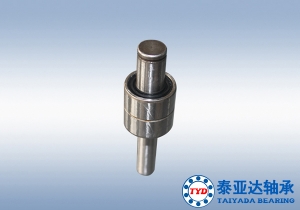

The automobile water pump shaft bearing is a type of bearing. The cage material is usually reinforced nylon 66, and the seal ring material is generally nitrile rubber. When the requirements are higher, fluorine rubber seals can also be used.

The cooling system of the car engine is an important part of the car. The stability and reliability of the system and the compactness of its structure. Not only directly affects the mechanical properties of the car, but also affects the overall appearance of the car. For this reason, automobile engine cooling systems produced by industrially developed countries generally use cooling water pump shaft bearings.

The role of the automobile water pump is to circulate the cooling water between the engine water jacket and the radiator to ensure that the engine works normally within a certain temperature range; the water pump is mainly composed of the shell, the pulley, the shaft and the bearing, the slip ring seal and the impeller The bearing has a decisive effect on the service life of the entire water pump, and also determines the main performance of the water pump such as noise.

Based on the structural characteristics of the shaft-connected bearing, the inner ring of the shaft as the bearing should have a contact fatigue life corresponding to the bearing. When the bearing is running, the surface of the raceway and the rolling element will form cracks and expand under the long-term action of the cyclic load, until the surface of the raceway or the rolling element is fatigued and peeled. Once such a situation occurs during the operation of the shaft-connected bearing, its vibration and noise will increase sharply, thereby making the whole machine unable to work. It can be seen that in order to improve the service life of the shaft-connected bearing, in addition to considering the wear resistance and fatigue strength required as a shaft, it must have a higher contact fatigue life.

The steel selected for conventional shaft bearings (including shafts, outer rings, steel ball rollers) is high carbon chromium bearing steel (GCr15). Because high-quality bearing steel is smelted through vacuum deoxidation, electromagnetic stirring, and has less oxide content, it can withstand greater contact pressure stress while also withstanding greater high variable tensile stress. After heat treatment, the hardness of the shaft raceway It is 58-62HRC. The hardness of the ring raceway is 60-64HRC, and the hardness of the steel ball and roller is 61-65HRC. When the shaft and outer ring are made of carburized bearing steel, the raceway hardness is 60-64HRC. The material of the cage is usually reinforced nylon 66, and the material of the sealing ring is generally nitrile rubber. When the requirement is higher, the fluorine rubber sealing ring can also be selected.

Because the water pump shaft bearing works at high speed and high temperature, the lubrication conditions directly affect the operating life of the shaft and shaft. Usually, imported high-grade grease with higher dropping point and better consistency is used, and the sealing ring is usually used. The large surplus radial contact seal ensures that the bearing does not lose oil for many years.

Precautions for the use of automobile water pump shaft bearings

1. Prevention of assembly foreign matter

When the bearing is installed on the rotor for dynamic balancing, it is easy for the iron filings generated during the dynamic balancing to enter the inside of the bearing, so it is better to perform dynamic balancing before installing the bearing. Some manufacturers apply some oil or grease to the bearing chamber for lubrication in order to facilitate assembly. However, it is often difficult for the operator to control the amount. If a lot of oil or grease accumulates in the bearing chamber, the bearing rotates on the water pump shaft. It is easy to enter the inside of the bearing along the shaft. It is better not to apply oil or grease to the bearing room.

2. Prevention of paint rust

The characteristic of lacquer rust is that it mostly occurs in sealed motors. The motor sounds very good during assembly, but after some time in the warehouse, the abnormal noise of the motor becomes very large, but the imported bearing of the water pump shaft is removed and there is serious rust. In the past, many manufacturers thought it was the problem of imported bearings, but now they have realized that it is mainly the problem of insulating paint. Such a problem occurs mainly because the acidic substance volatilized from the insulating paint forms corrosive substances at a certain temperature and humidity, which causes the bearing to be damaged after corroding the bearing channel. The only way to solve the problem is to choose a good insulating paint and ventilate for a period of time after drying and then assemble.

3. Selection and control of tolerances of shafts and bearing chambers

After the water pump shaft bearing is pressed into the imported bearing, it should rotate flexibly without any sense of blocking. If there is obvious inflexible rotation, it indicates that the size of the shaft is too large and the tolerance needs to be lowered. If the water pump shaft and the imported bearing are pressed into the shaft and turned by hand, there is an obvious feeling of "sand", it may be because the tolerance of the shaft is too large or the roundness of the shaft is not good. Therefore, when controlling the tolerance of the shaft and the bearing chamber, the roundness must be controlled. Many domestic manufacturers only control the tolerance but not the roundness.

4. The assembly method of the bearing

Because the bearing is a high-precision product, improper assembly of the water pump shaft can easily cause damage to the bearing channel of the water pump shaft and cause bearing damage. When assembling the bearing, a special mold should not be knocked at will. When the shaft is pressed into the shaft, only the small circle can be forced, and when the large circle is pressed, only the large circle can be forced. Air pressure or hydraulic pressure is required when assembling, and the up and down touch should be outside the horizontal state during press-fitting. If there is an inclination, the bearing channel will be damaged due to the force, which will cause the bearing to produce noise.