| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

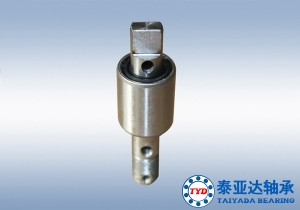

The split automobile water pump shaft bearing is more special in process design than other bearings, and is suitable for places with low speed, heavy load, high impact force and poor sealing performance. The editor of China Bearing Network learned from the Internet that many users will find that the operation of split bearings is not flexible when using split bearings. What is going on? We need to analyze the specific situation to find a solution.

After summarizing, it is found that the phenomenon of inflexible movement of the split automobile water pump shaft bearing is mainly reflected in three situations. The following describes the three phenomena of inflexible operation of the split bearing and the methods to be solved for different situations.

1. The newly assembled rotary split automobile water pump shaft bearing product does not run smoothly

① Check the production date of the split bearing. If it takes a long time and the climate is cold, it is possible that the grease in the raceway has a high viscosity, which may cause malfunction, which is more prominent in winter in cold areas.

② Newly assembled slewing split bearing product idling and not smooth solution: if it can run without other abnormalities after adding force, it can be used normally, if it is accompanied by abnormal noise, check whether there is any serious trauma during transportation.

2. The split bearing does not run flexibly after reassembly

① Exclude whether it is because the installation surface of the main machine and the installation surface of the split bearing are not well matched, which causes the axial clearance of the split bearing after installation to be unable to compensate for the deformation of the split bearing. The split bearing is in a state of negative clearance, and the rolling elements are difficult to run in the raceway (sometimes with abnormal noise); the large and small gears have poor meshing or foreign objects are stuck in the large and small gears.

② Elimination of inflexible operation of split bearing after reassembly

(1) Re-process the host installation plane to make the installation plane meet the requirements; or use the gasket filling method.

(2) Re-adjust the gear meshing backlash as required, especially pay attention to the gear jump position.

(3) Check to ensure that there is no foreign matter in the meshing position of the large and small gears.

(4) Replace a split bearing with a slightly larger clearance.

Third, the operation of split bearings in daily use is not flexible during use

① Lack of grease, fill it up as required.

② The sealing strip is damaged, causing foreign matter to enter the raceway (such as poor working conditions, dust intrusion into the raceway, etc.).

③ Check the meshing of the large and small gears, whether there are foreign objects or broken teeth.

Of course, when we buy split bearings, we also need to know some selection skills, so that we can get more suitable bearings and make machinery and equipment work better. China Bearing Network shares points to be aware of when choosing split bearings.

1. Choose according to the fixed load, because the fixed load has the characteristic that the composite radial load vector and the ferrule are relatively static.

2. The split bearing is selected according to the number of rotating loads, because the rotating load has the characteristic of rotating the composite radial load vector relative to the ring.

3. Choose according to the swing load and variable load of the split bearing. Swing load refers to the resultant load that the rotating load is much smaller than the fixed load. Swing load means that the load on some ferrules may sometimes be a rotating load, sometimes a fixed load, and sometimes a swing load.

Warm reminder: Because the ring and shaft or seat hole of the split automobile water pump shaft bearing vibration type need a certain transition fit or interference fit, when the interference size is based on the automobile water pump shaft bearing under load, the vibration type section The principle is that the bearing ring does not produce "creeping" phenomenon on the shaft or the mating surface in the seat hole.