| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

The water pump bearing needs to be cleaned with gasoline or kerosene before the installation, and it can be used in front of the dry, and it can ensure good smoothness. Water pump bearings generally use grease smoothness, of course, oil smoothness can also be used.

If the water pump bearing is smooth with grease, the smooth grease with superior performance such as anti-oxidation, anti-rust, no impurities and extreme pressure should be selected. The amount of smooth grease filled bearings and bearing boxes is generally 30%-60% of the volume to prevent too much.

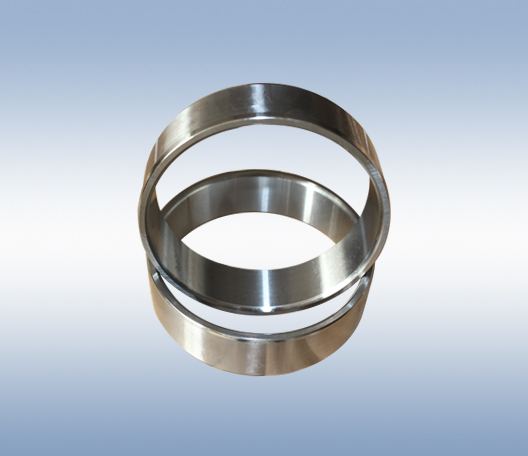

The material selected for the shaft bearing of the automobile water pump is steel, including the steel ball roller, outer ring, shaft and other materials are all high-carbon chromium bearing steel (GCr15). High-quality bearing steel undergoes vacuum deoxidation, electromagnetic stirring, and has relatively low oxide content. Therefore, while being able to accept greater contact compressive stress, it can also accept greater high-variable tensile stress. After bearing steel undergoes heat treatment, the raceway hardness of the shaft is generally 58-62HRC. The hardness of the steel ball and roller is 61-65HRC, and the hardness of the ring raceway is 60-64HRC.

When the outer ring of the car water pump shaft bearing is made of carburized bearing steel, the hardness of the raceway is 60-64HRC.