| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

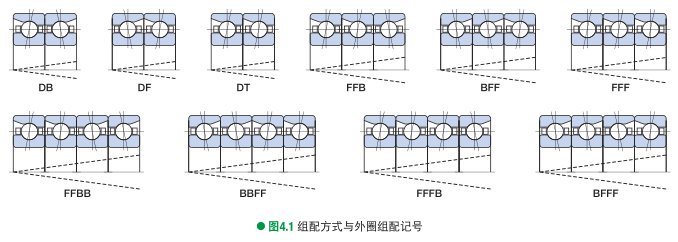

Precision bearing assembly method and application characteristics

Back-to-back equipment (DB)

● Accept radial load and axial load in two directions

● Because of the long interval between the load centers, the moment load has high rigidity

● Device faults such as point-of-view faults can simply lead to increased internal load and damages such as early drops.

Face-to-face equipment (DF)

● Because the load center interval is short, the moment load rigidity is weak

● Since the moment load has a weak rigidity, it can suppress the increase of the internal load caused by the wrong viewpoint, etc. Therefore, it is suitable for use when the viewpoint cannot be prevented from being wrong or the shaft is bent due to load. Tandem equipment (DT)

● Accept radial load and axial load in one direction

● The axial load capacity is twice that of single-row bearings, so it is suitable for

When the axial load in one direction is large.

3-row equipment (FFB)

● Accept radial load and axial load in two directions

● The axial load in one direction is twice that of a single-row bearing, but because the preload distribution of each bearing is unequal, the single-row side is twice that of the 2-row side. When rotating at high speed, the unequal distribution of preload brings difficulties to the reasonable setting of preload.

4 rows of equipment (FFBB)

● Accept radial load and axial load in two directions

● Under the same preload clearance, the preload of back-to-back equipment is increased by 2 times, and the rigidity is enhanced

Table 4.1 Primary assembly methods and characteristics