| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

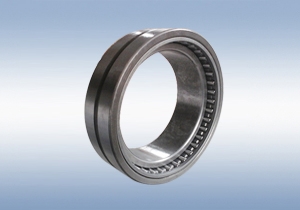

Precautions for the use of roller needle roller bearings of Changzhou Taiyada Bearing Co., Ltd.:

1. The installation of full complement needle roller bearings is usually carried out by using auxiliary sleeves, and the needle roller bearings and related components are often cleaned;

2. Needle roller bearings have large load-bearing capacity and are suitable for supporting structures with restricted installation dimensions. The journal surface is hardened as the rolling surface, and the bearing is fitted into the seat hole with press fit, so there is no need to axially locate it.

3. Check the size of parts and arrange related needle roller bearings

4. The bearing should be filled with a proper amount of grease before installation. Under normal circumstances, it is not necessary to relubricate after assembly.

5. With high-speed rotating bearings or bearing instruments, the application of cleaning oil in cleaning oil will wash away rust

6. The bearing is easy to rust and cannot be placed for a long time.