| (Service Hotline) 0519-86365509 |

Contact: Shi Lijie +86 15851987186 (same number on WeChat)

Shi Jianlin +86 13806110378 (WeChat account)

Q Q: 657352779

Production room telephone: +86 519-86358076

General Manager Tel: +86 519-86365509

Fax: +86 519-86365069

E-mail: 657352779@qq.com

Website: en.czxmzc.com

Address: No. 98, Weijiaqiao, Niutang Industrial Park, Wujin District, Changzhou City

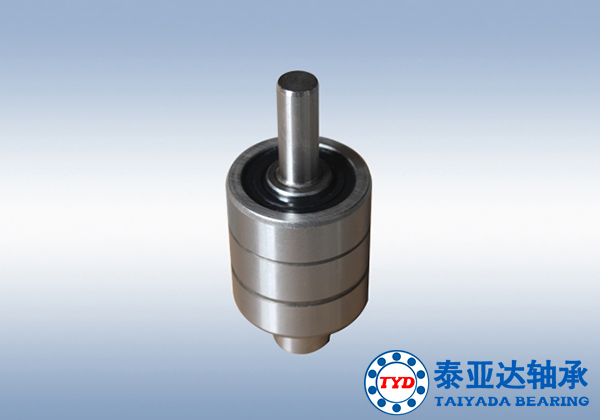

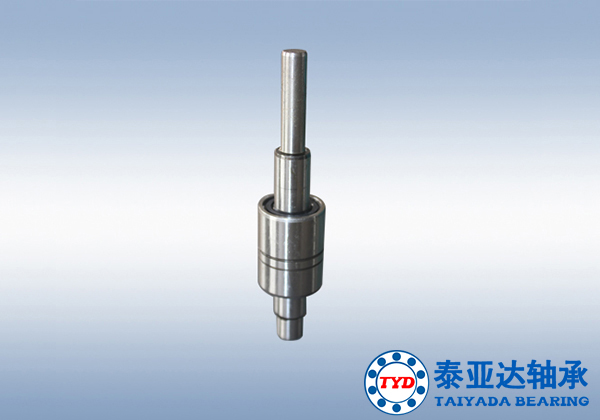

Jiangsu Changzhou Taiyada Bearing Co., Ltd. will take you to understand the disassembly and installation of automobile water pump shaft bearings, as follows:

1. Disassembly of bearing:

When the bearing is to be used after being removed, an appropriate removal tool should be used. When disassembling the ferrule with interference fit, only the pulling force can be applied to the ferrule, and it is never allowed to transmit the disassembly force through the rolling elements, otherwise the rolling elements and raceways will be crushed.

2. Bearing installation:

The installation of the bearing must be carried out under dry and clean environmental conditions. Before installation, carefully check the processing quality of the mating surface of the shaft and the housing, the end surface of the shoulder, the groove and the connecting surface.

All mating and connecting surfaces must be carefully cleaned and deburred. The unprocessed surface of the casting must be cleaned of sand.

Before the bearing is installed, it should be cleaned with gasoline or kerosene, and used after drying, and ensure good lubrication. The bearing is generally lubricated with grease or oil. When grease lubrication is used, greases with excellent performance such as no impurities, anti-oxidation, anti-rust and extreme pressure should be selected. The amount of grease filled is 30%-60% of the volume of the bearing and the bearing box, and should not be too much. The double-row tapered roller bearing with sealed structure and the water pump shaft bearing have been filled with grease, and the user can use it directly without cleaning.

When the bearing is installed, an equal pressure must be applied to the circumference of the end face of the ring to press the ring in. It is not allowed to directly knock the end face of the bearing with a tool such as a beetle to avoid damage to the bearing. In the case of small interference, the end face of the bearing ring can be pressed with a sleeve at room temperature, and the sleeve can be knocked with a zou head, and the ring can be pressed in evenly through the sleeve. If installed in large quantities, hydraulic presses can be used. When pressing, ensure that the end face of the outer ring and the end face of the housing shoulder, and the end face of the inner ring and the end face of the shaft shoulder are pressed tightly, and no gap is allowed.

When the interference is large, oil bath heating or induction heating bearing method can be used for installation. The heating temperature range is 80℃-100℃, and cannot exceed 120℃. At the same time, use nuts or other appropriate methods to tighten the bearing to prevent the bearing from shrinking in the width direction after cooling and causing a gap between the ring and the shaft shoulder.

The clearance of single row tapered roller bearings should be adjusted at the end of installation. The clearance value should be specifically determined according to different operating conditions and the size of the matching interference. If necessary, it should be tested to determine. The double-row tapered roller bearings and the water pump shaft bearing have been adjusted in clearance before leaving the factory, so there is no need to adjust them during installation.

After the bearing is installed, a rotation test should be carried out. First, it is used for the rotating shaft or bearing box. If there is no abnormality, it will run with no load and low speed with power, and then gradually increase the rotation speed and load according to the running situation, and detect noise, vibration and temperature rise If abnormality is found, stop the operation and check. It can be used after the operation test is normal.

Our products include automotive water pump bearings WB and WR series, and needle roller bearings NA, RNA, NK, NKI, IR, NATR, NUTR, KR, NKIA, NKIB, NKX, NKXR and other series. Welcome new and old customers at home and abroad to contact us for business cooperation.